Print heads - Flathead and Near Edge: What are they and what are the pros and cons?

If you've decided that you need thermal transfer technology, then the next thing you need to know is that there are two types of print head used in thermal transfer printing::

It’s certainly worth understanding the difference and assessing which one will suit your business best. (Especially if you might need the useful additional feature only available with Near Edge -see point 5).

The names ‘Flathead’ and ‘Near Edge’ refer to angle of the print head and the positioning of the heating element. This determines the way that the print head makes contact with the ribbon and the label surface, which impacts:

- Speed

- Intensity of the image

- The ability to save wastage

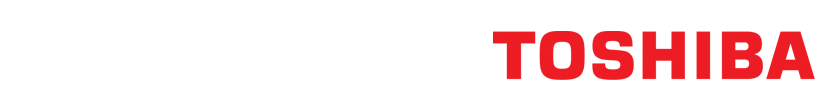

Flathead

In Flathead technology, the print head lies flat against the ribbon and the label stock, with the heating element in the centre.

The heating element is further from point where the label exits the printer, so the label takes longer to travel from heating element to exit. This gives it time to cool down, so the labels leave the printer already cool. That’s why this technology is often referred to as the ‘cold peeling method’

The type of print technology you choose will very much depend on what you are labelling and why. You’ll need to take into account how the labels will be used - their expected life and their treatment during their life, remembering that the primary goal of your label is to remain legible,

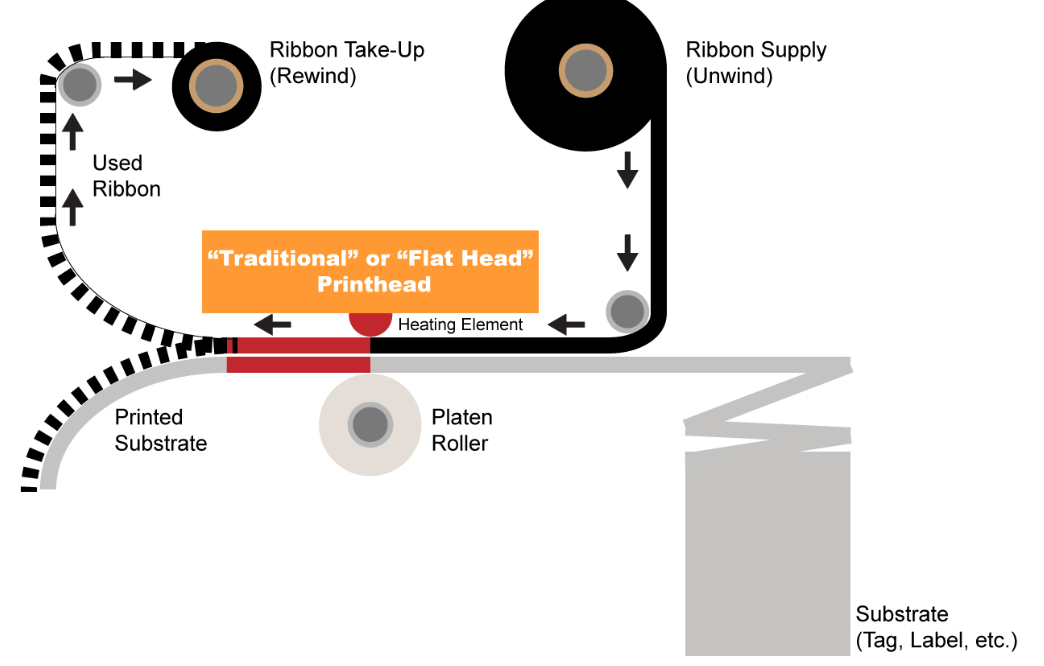

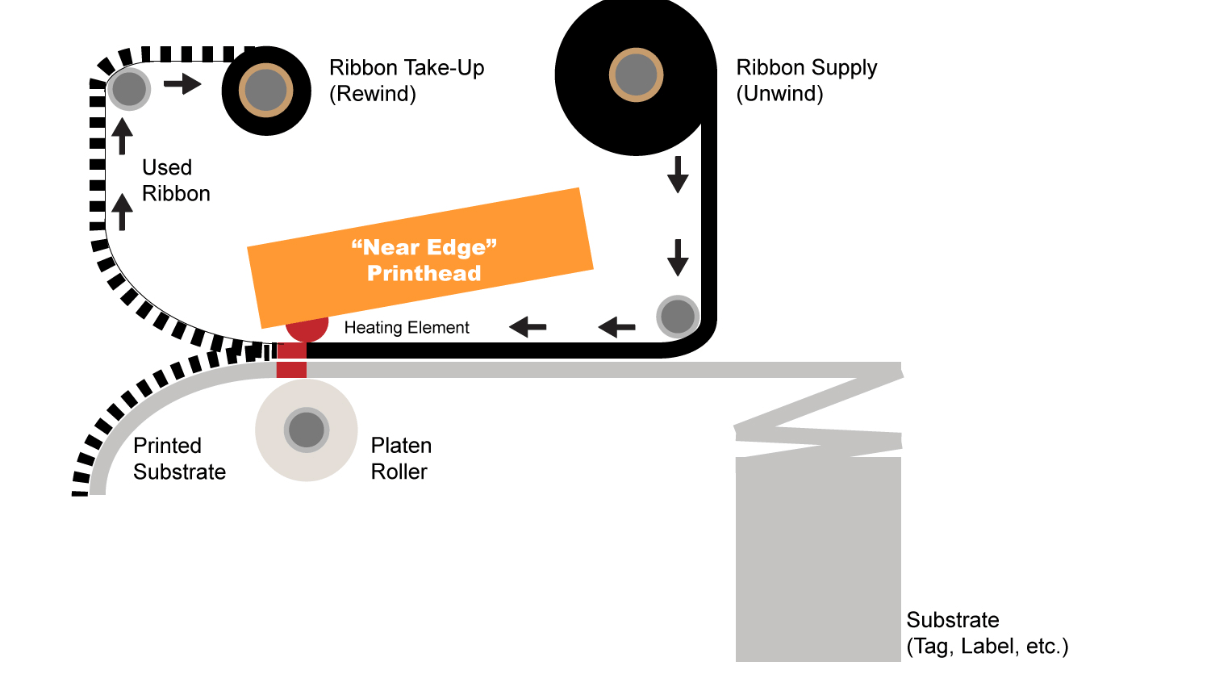

Near Edge

In Near Edge technology, or the ‘hot peel method’, the print head sits at an angle to the ribbon and paper, only making contact for a much shorter time. The heating element is at the lower end, close to the exit point. The heating element therefore has to heat and transfer the ink much faster, because of its limited contact time. With the heating element close to the edge, the labels are warm and the ink still setting as they exit the printer.

So much for the explanation, but what does this all mean for your business? What are the pros and cons of each type of print head and which one is right for you?

Flathead - Pros

- Darker print - because the head is in contact with the ribbon and label for longer, the print density (measured in dots per inch, or DPI) is greater. Typically, a flathead printer can print at up to 600 DPI.

Flathead - Cons

- Slower - because of the distance and time between the heating element and the exit, flathead printers are slower than Near Edge. For example, a high speed flathead might print at 6-10 inches per second. (It’s worth noting here, that when we talk of print speeds, we mean the speed at which the device can print well. You will see claims of faster speeds for Flathead devices, but this is often at the expense of patchy, faint, illegible print.).

Near Edge - Pros

- Faster printing - because the print head is in contact with the ribbon and label stock for less time, the labels can move through the printer faster. A Near Edge print head can achieve speeds of up to 14 inches per second (and print well).

- Print heads last longer - Heating is one of the factors that causes a print head to wear out, so because Near Edge print heads have a shorter heating time, they last longer.

- Longer warranty - less heating time also means that you’ll get a longer warranty on a Near Edge print head - typically 100 km rather than 50km. (Yes, print head usage is measured in kilometres!).

- Option for extra features - Near Edge technology offers the possibility of the cost efficiency option ‘Ribbon Save’. (We look at this in point 5 - Additional Features).

Near Edge - Cons

- Lower density - Near Edge printing doesn’t have the same density as Flathead, again, because the print head has less contact time with the ribbon and paper. Typically, a Near Edge print head will have half the DPI of Flathead.

So when you’re deciding on your printer purchase, and are looking at thermal transfer, do consider the type of print head which will best suit your business.

Matching the print head and the ribbon

One other point on print heads - whichever one you choose, be aware that the ribbon needs to match the print head. There are different ribbons for Flathead and Near Edge. This is because a ribbon is made up of layers (five), one of which determines the way the ink is released. The ink release mechanism is different for each print head type, so it’s essential to match the ribbon type and the print head type.